What’s the Difference with Dual Action, Random Orbit, and Rotary Buffers

There are so many types of polishers

For the sake of this article we are going to refer to buffers, buffing machines, polishing machines, etc. as polishers. This is going to be a very basic introduction into the world of polishers so that you can easily understand what they do and which one is right for you.

First let us define what a polisher is in the detailing world. To detailers, polishers are a mechanical tool used to improve the appearance of paint on vehicles through the use of abrasion. They come in all shapes and sizes but generally have a handle with the motor inside and a backing plate where a buffing pad will go. The concept is that the motor spins the pad and the pad then abrades against the paint with a polish, compound, or wax between the paint and the pad. Polishes, compounds, and waxes will be an entirely different topic which we will discuss later.

If you are someone who is trying to find the best polisher for themselves, first ask yourself a few questions.

- What's your budget? ($50? $150? $500?)

- Do you plan on doing this professionally or at home use?

- Do you have any experience with these types of machines?

- How much correction do you plan on getting, if any at all?

- Standard Orbit Polishers

- Random Orbit Polishers

- Forced Rotation Dual Action Polishers

- Rotary Polishers

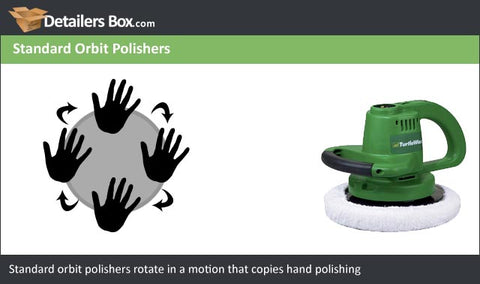

Standard Orbit Polishers

A standard orbit polisher is your most common (in store and at home) use polisher. They can be found at most major auto parts stores and many home goods stores. They are not seen in professional use for their lack of strength and capabilities. For a professional detailer, the best this can do is apply a wax or sealant. Don't expect much paint correction with using one of these, but they are much easier to use than your bare hands. And that is exactly what a standard orbit polisher does. Think of how your hand moves while polishing a car. You move in circular motions and that is how a standard orbit polisher works. They do not spin like a drill but rather rotate around in a circle as demonstrated in the picture below.

Pros

- Inexpensive

- Easy to use

- Easy to find locally

Cons

- Weak

- Cannot perform paint corrections

- Very little use besides waxing

Random Orbit Polishers

Random orbit polishers are sort of a combination of rotary and standard orbit polishers. The speed of a random orbit polisher is counted in orbits per minute (OPM). [highlight]Unlike a rotary which is forced to spin, a random orbit polisher actually rotates from the momentum created by the high speed orbital motion.[/highlight] There is no direct link between the rotations and orbit making this machine very safe and easy to use for beginners. The pattern is truly random as the combination of stroke length, pad size, pad grip, and speed can alter the pattern of motion. Some popular random orbital polishers include the Rupes LHR21ES, Porter Cable 7424XP, and the Meguiar's G110.

Pros

- Good for learning

- Fairly easy to handle and use

- Basic random orbits are very affordable

Cons

- Not as strong as a rotary

Forced Rotation Dual-Action Orbital Polishers

A forced rotation dual action orbital polisher is a mouthful to say. What this polisher does is combine both the rotary and orbitals motions into one forced action. [highlight]The difference between this and a random orbit polisher is that a forced rotation drives both the rotating and orbiting motions. [/highlight]A random orbit only drives orbit and relies on momentum to rotate the pad. These machines force both orbit and rotation. This means that a forced rotation dual action orbital polisher has a consistent pattern. They are as easy to use as a random orbit but slightly more dangerous as heat can build up faster on these types of polishers. Some examples of Forced Rotation D/A polishers include the Flex XC3401 VRG.

Pros

- Stronger than a random orbit polisher yet safe for beginners

Cons

- Fixed backing plate (limited options)

Fixed rotation can limit it's polishing capabilities

Rotary Polishers

Rotary polishers are simple in concept but much more difficult to control and master than random orbital polishers. [highlight]Rotary polishers spin the pad in a circular motion as seen in the diagram below.[/highlight] This consistent motion causes a lot of friction (which is also cut) but friction causes heat. This extreme heat is dangerous and can damage a vehicles finish. The consistent pattern in a rotary can very easily create what is known as holograms in a paints surface so caution has to be used with a rotary polisher. Some common rotary polishers include the DeWalt DW849, Flex L3403 VRG, andMakita 9227C.

Pros

- Unparalleled cut and capability

- Stronger than any other type of machine

Cons

- Very difficult to use (not recommended for beginners)

- Can easily damage a paints surface

So which polisher is right for you? Go through the Pro's and Con's of each type of machine polisher and make the best decision you can. We recommend amateurs and beginners start with a machine like the PC 7424XP as they are affordable and easy to use. With a good pad and polish combo such as a Meguiar's Microfiber Cutting Disc and HD Adapt a beginner can get on his way to amazing levels of correction! If you want something still easy to handle but more advanced, the Rupes LHR15ES is a very stout machine and with a little modification, they can be as good as it gets.